The Environmental Monitoring Program has become a key element of Food Safety Management Systems today to eliminate food safety risks and prevent product returns. The Food Industry, which has focused on biological threats and production outputs from the past to the present, now believes that food safety is directly related to contamination from environmental conditions such as production sites, equipment & personnel.

What is an Environmental Monitoring Program?

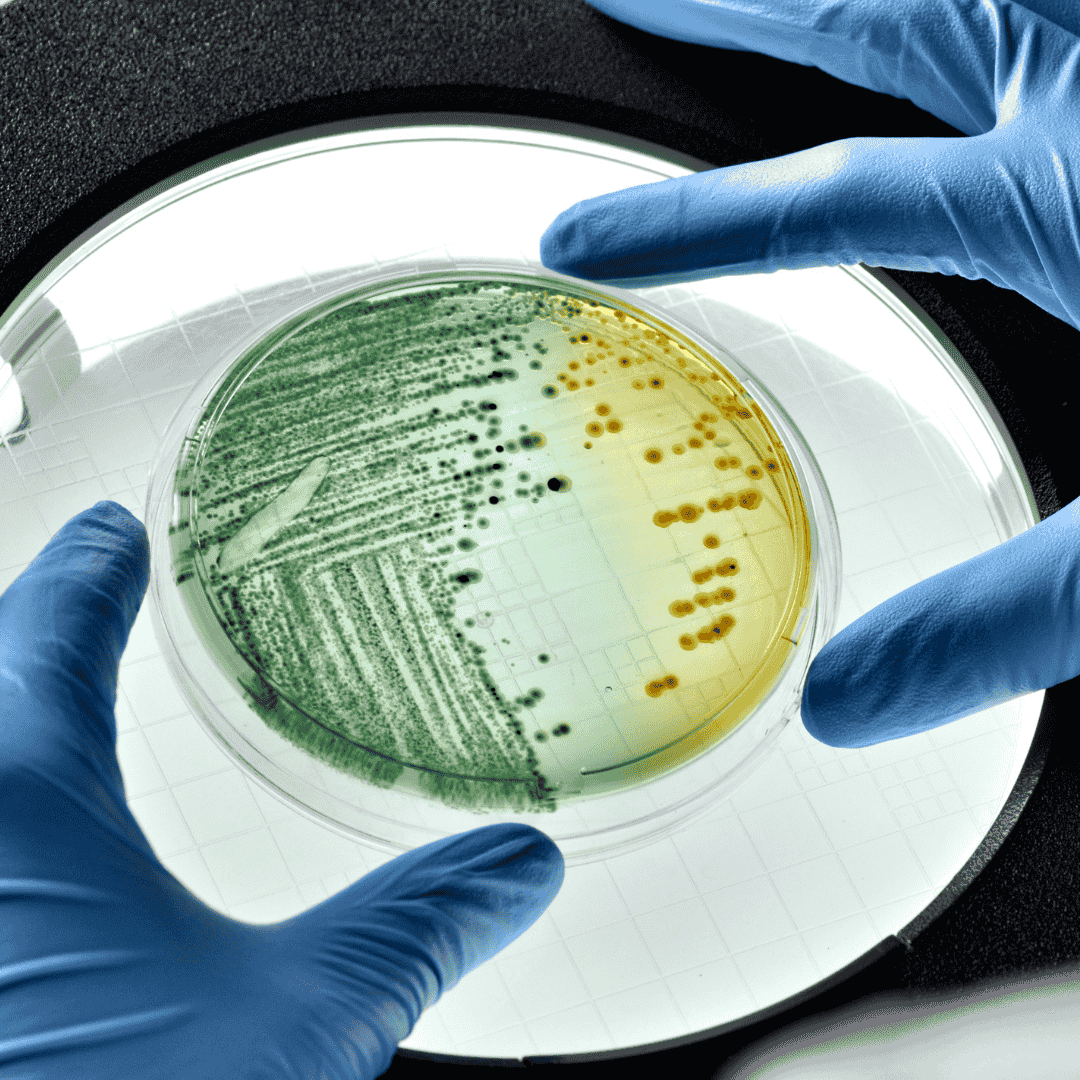

Environmental monitoring is a system that aims to detect the presence of pathogens that may cause disease or spoilage in the production environments of food production or food packaging and to eliminate those detected. First, sanitation and hygiene points are determined in the system, the next step is to determine the sample dates and periodic frequencies to be taken from these points. At the next stage, it is decided which types of microorganisms will be monitored. It covers test methods, periods, approval criteria, corrective actions in case of pathogen or contamination detection.

Benefits of an Environmental Monitoring Program

Food sites and production stages are very suitable environments for the growth, survival and development of pathogens (microorganisms). Microorganisms can be transported to production areas through raw materials, packaging, waste water drains, air systems, personnel or pests. Food manufacturers try to control microbiological risks in accordance with prerequisite programs and HACCP principles. The identification of microbiological threats and the production site has prioritized environmental cleaning plans. However, the effects of microorganism growth caused by environmental factors on product safety and food health were later recognized.

We can list the benefits of the program as follows;

- Controlling pathogens

- Explore locations and areas where microorganisms occur

- Taking action when an infection/transmission is detected

- Verification of the food safety system

- Verification of hygiene, sanitation and cleaning plans

- Eliminate product food safety risks and prevent product returns

Stages of an Environmental Monitoring Program?

- Create an EMP team working in different departments.

- Don’t forget to update factory layout and HACCP workflow diagrams

- Classify the microorganisms to be analyzed (primary and secondary)

- Review your business pathogen history

- Conduct a product risk assessment

- Create zones areas and sampling points

- Determine your sampling techniques and test methods

- Data analysis and reporting

- Continue to apply consistently

The risk assessment of the environmental monitoring program requires an effective approach, so areas in direct contact with the product, air and personnel are considered the program’s top priority areas. Taking these risks into account, production sites, interiors and factories are divided into four (4) zones. Remember to implement different plans for each zone.