A robust food sanitation program forms the backbone of food safety in any production or handling environment. The complexity of modern food systems demands meticulous attention to cleanliness and contamination prevention. Below is a comprehensive breakdown of the essential elements:

1. Comprehensive Sanitation Plans

A sanitation plan serves as the foundation for achieving consistent hygiene standards. Key components include:

- Sanitation Standard Operating Procedures (SSOPs):

SSOPs provide a detailed framework for cleaning and sanitation activities, including:- Step-by-step instructions for cleaning specific surfaces, equipment, or utensils.

- Cleaning frequencies tailored to different areas (e.g., daily for processing lines, weekly for storage areas).

- Assigned responsibilities for personnel ensuring accountability.

- Master Cleaning Schedule:

A visual and actionable schedule that includes:- The cleaning frequency of each facility area and equipment.

- Designated shifts or times for deep cleaning to minimize disruption to production.

- Allocation of specialized tasks like disinfection, spot cleaning, or pressure washing.

2. Proper Employee Training and Engagement

Employees are the first line of defense in a sanitation program. Proper training and ongoing engagement ensure consistent compliance. Key topics to cover include:

- Personal Hygiene Practices:

- Proper handwashing techniques and frequency.

- Wearing appropriate protective clothing, such as gloves, hairnets, and face masks.

- Clear policies for illness reporting to avoid contamination risks.

- Effective Chemical Handling:

- Knowledge of Material Safety Data Sheets (MSDS) for cleaning agents.

- Correct mixing and dilution protocols to maintain effectiveness without waste.

- Role-Specific Training:

- Regular drills for sanitation tasks involving critical equipment.

- Cross-training programs to ensure flexibility in covering tasks.

3. Cleaning and Sanitization Protocols

Each step of the cleaning process must be thorough and validated. Steps include:

- Pre-Cleaning: Remove loose debris using tools like brooms or scrapers.

- Cleaning with Detergents: Apply food-safe cleaning agents to dissolve grease and organic material.

- Rinse Procedures: Ensure complete removal of residues using potable water.

- Sanitization: Apply a sanitizer that is appropriate for food contact surfaces, and ensure it has adequate contact time as specified.

- Verification: Check for visible cleanliness and, if possible, perform chemical residue tests.

4. Monitoring and Verification Systems

Regular monitoring and verification are crucial to ensure compliance with hygiene standards. Techniques include:

- Environmental Monitoring Programs (EMPs):

- Place sampling swabs on various surfaces, including food contact zones and hard-to-reach areas.

- Conduct microbiological testing to detect Listeria, Salmonella, and other pathogens.

- ATP Testing: Use rapid tools to measure the organic matter remaining on a surface post-cleaning, which provides real-time feedback.

- Routine Inspections: Establish a checklist covering key areas such as floors, drains, storage units, and frequently used equipment.

- Trend Analysis: Record and analyze data from testing to spot recurring issues and improve procedures.

5. Pest Control Management with Integrated Approaches

Pests pose a significant risk to food safety, making pest control a critical part of a sanitation program. Essential practices include:

- Preventive Maintenance:

- Sealing entry points, such as windows, vents, and cracks in walls.

- Installing air curtains or strip doors to deter flying pests.

- Monitoring and Trapping Systems:

- Regular placement of glue traps, bait stations, and insect light traps.

- Continuous surveillance using digital tools for real-time pest activity reporting.

- Chemical Control Measures:

Use approved pest control chemicals in alignment with local food safety regulations.

6. Hazard Analysis and Risk-Based Controls

Understanding the risks of contamination allows for targeted preventive actions. Implement the following:

- Zoning Strategies:

- Establish separate areas for raw materials, processing, and finished products.

- Use color-coded tools and clothing to limit cross-contamination between zones.

- Critical Control Points (CCPs):

Identify and monitor areas most vulnerable to microbial contamination, such as conveyor belts and mixing tanks.

7. Regulatory and Standards Compliance

Complying with national and international food safety standards ensures both customer trust and legal adherence. Examples include:

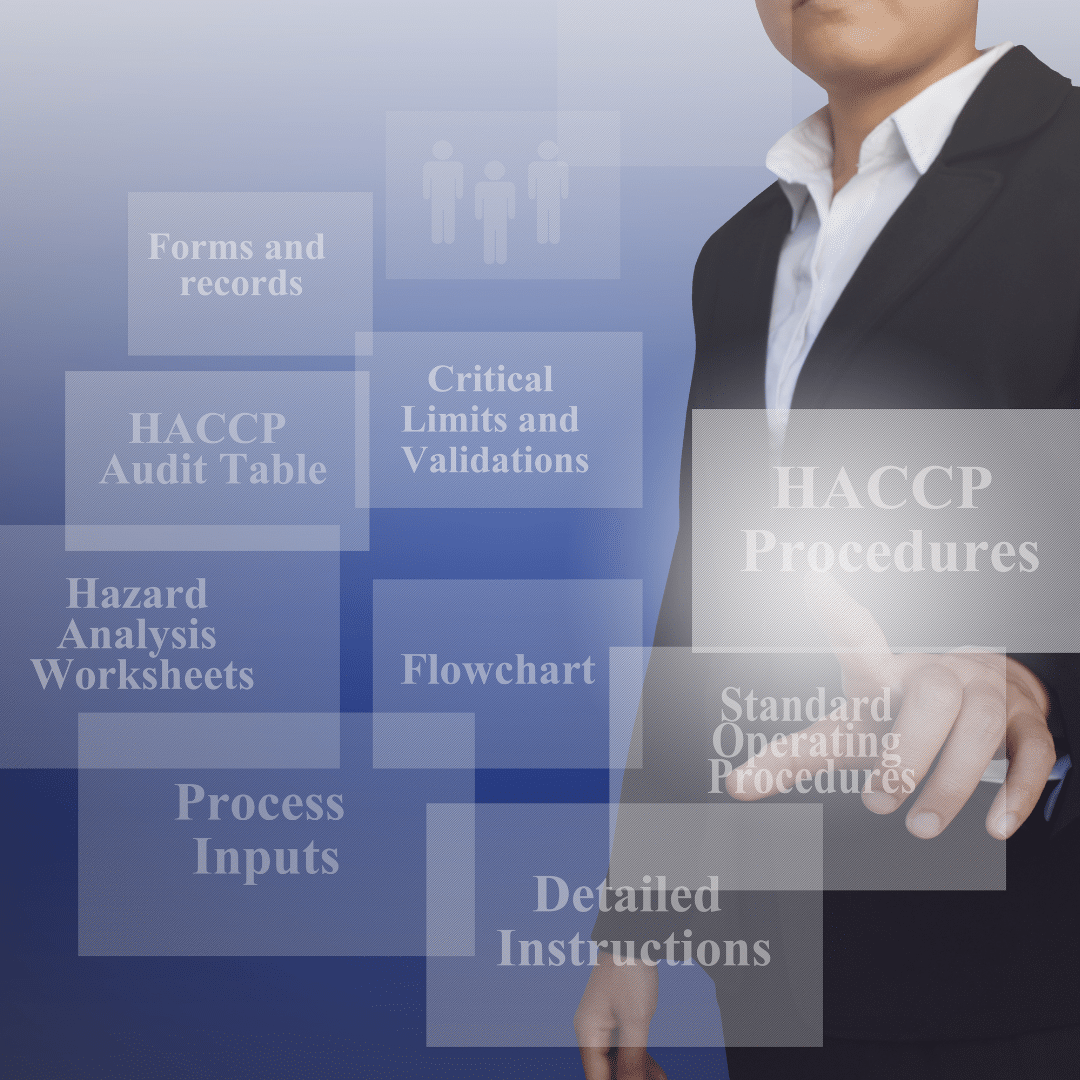

- HACCP (Hazard Analysis and Critical Control Points):

A systematic approach to identifying, evaluating, and controlling hazards. - GFSI (Global Food Safety Initiative):

Follow best practices outlined in schemes like BRCGS, IFS, and FSSC 22000. - Local Standards and Guidelines:

Stay updated on national food safety laws (e.g., FDA’s FSMA in the U.S.).

8. Documentation and Record-Keeping

Accurate records demonstrate adherence to standards and facilitate traceability during audits or recalls. Focus on documenting:

- Cleaning logs, including the date, time, and responsible individual.

- Results of microbiological and chemical testing.

- Records of employee training sessions and assessments.

9. Technological Enhancements

Automation and technology can enhance the effectiveness of sanitation programs, such as:

- Automated Cleaning-in-Place (CIP) Systems: Eliminate human error by automating equipment cleaning processes.

- IoT-Enabled Monitoring Tools: Continuously monitor air and water quality within the facility.

- Sanitation Management Software: Track schedules, test results, and performance metrics in real time.

10. Continuous Improvement Culture

A sanitation program should evolve as challenges and technologies change. Strategies include:

- Feedback Loops: Act on input from employees, customers, and audit results to refine processes.

- Research and Adaptation: Stay informed about new pathogens, cleaning technologies, and regulatory updates.

Implementing a comprehensive and dynamic food sanitation program is not merely a regulatory requirement—it’s a business imperative. Addressing each element thoroughly ensures clean and safe operations, upholds consumer confidence, and protects public health.

For food companies seeking an efficient and reliable way to manage their sanitation programs, Qualiqo provides an all-in-one solution. Designed to streamline food safety and sanitation management processes, Qualiqo enables businesses to track cleaning schedules, verify sanitation tasks, and ensure compliance with food safety standards through its powerful features like audit management, real-time alerts, and traceability. With Qualiqo, food businesses can transition smoothly into digital transformation while strengthening their commitment to food safety and sanitation.

Did you get enough information about “Integrated Pest Management (IPM) in Food Safety“

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control. We also provide information about the main features and benefits of the software. We help you access the Qualiqo demo and even get a free trial.

Frequently Asked Questions

Comprehensive sanitation plans (SSOPs and cleaning schedules).

Employee training and engagement.

Effective cleaning and sanitization protocols.

Monitoring and verification systems.

Integrated pest management.

Compliance with food safety standards.

Programs must comply with local and international standards such as:

HACCP (Hazard Analysis Critical Control Points).

FSMA (Food Safety Modernization Act).

ISO 22000 and other industry-specific certifications.

By implementing an Integrated Pest Management (IPM) approach, focusing on preventive measures, routine monitoring, and safe pest control methods.