Ensuring Safety at Every Step for Food Manufacturing Companies

In the realm of food manufacturing, safety isn’t just a priority; it’s a non-negotiable imperative. From raw materials sourcing to the final product reaching the consumer’s plate, every step in the food production process demands meticulous attention to safety controls. In this blog, we’ll delve into the preventive measures and safety protocols essential for food manufacturing companies to uphold.

1. Rigorous Supplier Screening and Quality Assurance

The journey to safe food begins with sourcing high-quality raw materials. Food manufacturers must establish stringent criteria for selecting suppliers. This involves thorough background checks, assessments of their adherence to safety standards, and continuous monitoring of their performance. Regular audits and certifications ensure that suppliers maintain consistency in delivering safe ingredients.

2. Implementing Hazard Analysis and Critical Control Points (HACCP) System

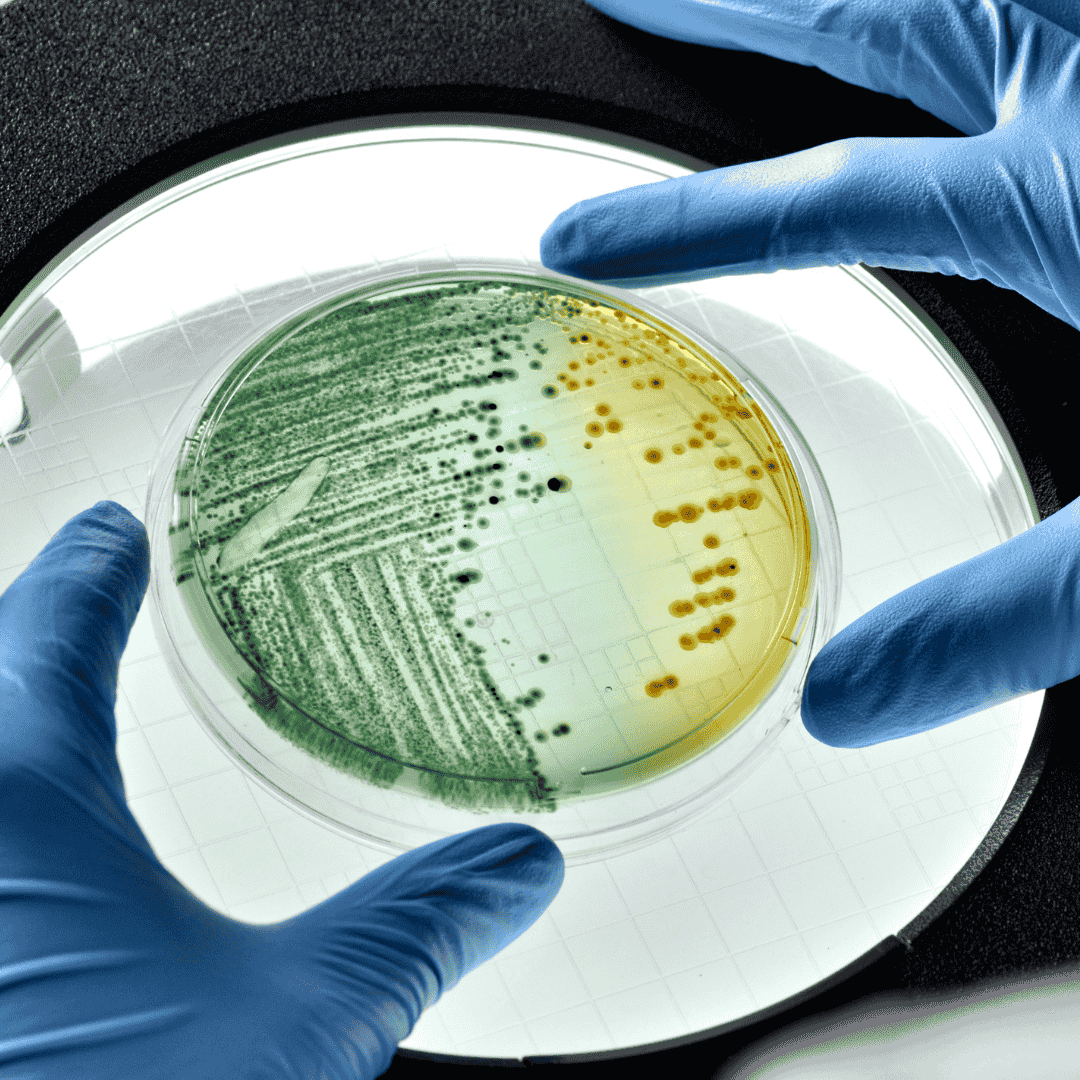

The HACCP system is a cornerstone of food safety management. It involves identifying potential hazards in the production process, determining critical control points (CCPs), and establishing measures to control these points. By proactively addressing risks, such as microbial contamination or chemical hazards, companies can prevent issues before they occur, safeguarding both consumers and their reputation.

3. Adherence to Good Manufacturing Practices (GMPs)

Good Manufacturing Practices are the foundation of food safety. They encompass a set of guidelines and protocols designed to ensure the consistent quality and safety of food products. This includes maintaining clean and hygienic facilities, proper sanitation procedures, employee training on food handling practices, and the use of appropriate equipment and utensils.

4. Robust Sanitation and Cleaning Procedures

Effective sanitation and cleaning procedures are paramount in preventing the spread of contaminants and pathogens. Food manufacturing facilities must establish comprehensive cleaning schedules, use approved sanitizers, and implement thorough cleaning protocols for equipment, surfaces, and production areas. Regular inspections and validation of cleaning efficacy are essential to maintaining a hygienic environment.

5. Training and Education for Employees

Employees are the frontline defenders of food safety. Comprehensive training programs are vital to ensure that all staff members understand their roles and responsibilities in maintaining safety standards. This includes education on proper food handling, hygiene practices, allergen management, and emergency procedures. Ongoing training and reinforcement foster a culture of vigilance and accountability throughout the organization.

6. Continuous Monitoring and Quality Control

Monitoring the production process in real-time allows for early detection of any deviations from established safety parameters. Advanced technologies, such as sensors, data analytics, and automation, enable companies to monitor critical variables like temperature, humidity, and microbial activity. Additionally, routine quality control checks and product testing verify the integrity and safety of the final products before they reach consumers.

7. Traceability and Recall Preparedness

In the event of a safety issue or contamination incident, swift action is crucial to mitigate risks and protect consumers. Food manufacturers must implement robust traceability systems that enable them to track ingredients and products throughout the supply chain. This facilitates prompt recalls if necessary, minimizing the potential impact on public health and brand reputation.

Safety is the cornerstone of trust in the food industry. Food manufacturing companies have a responsibility to uphold the highest standards of safety at every stage of the production process. By implementing rigorous preventive measures, adhering to established safety protocols, and fostering a culture of continuous improvement, these companies can safeguard the well-being of consumers and uphold their commitment to delivering safe, quality products.

Did you get enough information about “Preventive Measures and Safety Controls”?

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control. We also provide information about the main features and benefits of the software. We help you access the Qualiqo demo and even get a free trial.

Frequently Asked Questions (FAQ)

Key safety concerns in food manufacturing include microbial contamination, allergen cross-contact, chemical hazards, physical hazards (such as foreign objects), and foodborne illnesses.

Food manufacturers ensure the quality of raw materials through rigorous supplier screening, quality assurance programs, regular audits, certifications, and continuous monitoring of supplier performance.

Food manufacturing companies handle allergen management through segregation of allergenic ingredients, proper labeling, sanitation practices to prevent cross-contact, employee training on allergen handling, and implementing allergen control programs.