Ensuring the Safety of Your Products and Brand

In the fast-paced and highly regulated food industry, effective risk management is paramount to ensuring the safety, quality, and compliance of food products. Food safety risks, from contamination to regulatory violations, can have serious consequences for manufacturers, consumers, and businesses as a whole. Implementing a robust risk management system is critical in identifying, assessing, and mitigating these hazards, safeguarding your products and reputation.

At the heart of successful food safety management is understanding how to approach risks. Risk management in food safety goes beyond just identifying potential threats—it involves a continuous cycle of hazard analysis, control, and monitoring. By implementing an effective risk management strategy, food manufacturers can prevent incidents that could lead to costly product recalls, consumer health risks, and brand damage.

Why Risk Management in Food Safety is Essential

The importance of risk management in food safety cannot be overstated. Foodborne illnesses are a serious public health concern, and the consequences of contamination can be far-reaching. For manufacturers, the financial and reputational damage of a food safety failure can be severe, with the potential for legal actions, recalls, loss of consumer trust, and market share. Beyond consumer health, businesses also need to consider regulatory compliance, as governments worldwide are tightening food safety standards.

A comprehensive risk management system provides food manufacturers with the tools to:

- Identify and mitigate potential hazards.

- Ensure compliance with local and international regulations.

- Protect consumer health and trust.

- Reduce the likelihood of product recalls and other disruptions.

- Enhance operational efficiency and accountability.

Key Components of Effective Risk Management in Food Safety

1. Hazard Identification

The first step in any risk management strategy is identifying potential hazards. Hazards can be broadly categorized into three main groups:

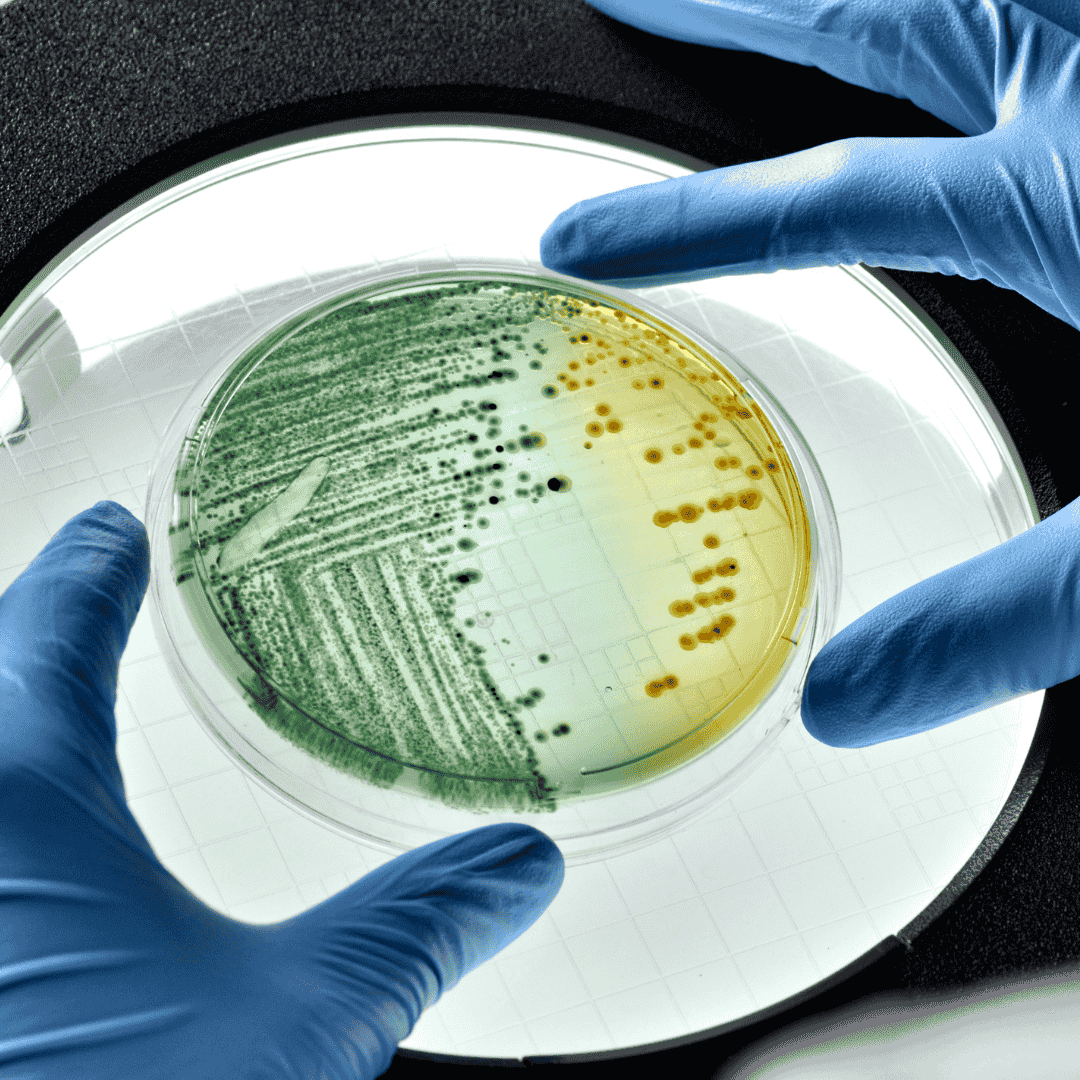

a. Biological Hazards

These include bacteria, viruses, parasites, and fungi. Common examples include E. coli, Salmonella, and Listeria. These pathogens are often a primary concern in food safety, especially in raw and perishable products.

b. Chemical Hazards

These can be either naturally occurring or introduced through contamination. Examples include pesticides, allergens, food additives, heavy metals, and contaminants like melamine.

c. Physical Hazards

These involve foreign objects that could accidentally enter food products, such as glass, metal shards, or plastic. These hazards pose a direct safety risk and could lead to injury or loss of product integrity.

Once hazards are identified, it’s important to assess their potential to cause harm. This is where the risk assessment phase comes into play.

2. Risk Assessment

Risk assessment helps determine the severity and likelihood of each hazard. A key part of this process is evaluating the risk factors:

a. Likelihood of Occurrence

How likely is it that the hazard will affect the product? Factors such as raw material sourcing, environmental conditions, and processing methods influence this probability.

b. Severity of Impact

What would the consequences be if the hazard materializes? A contamination outbreak might lead to a large-scale recall or health issues among consumers.

c. Exposure Level

How many consumers could be affected by the hazard? Some hazards may only pose a local risk, while others could have a more widespread impact.

The goal of the risk assessment phase is to prioritize risks based on their potential impact and likelihood of occurrence. Risks that present the highest threat should be addressed first, while lower-risk hazards can be managed through monitoring and control.

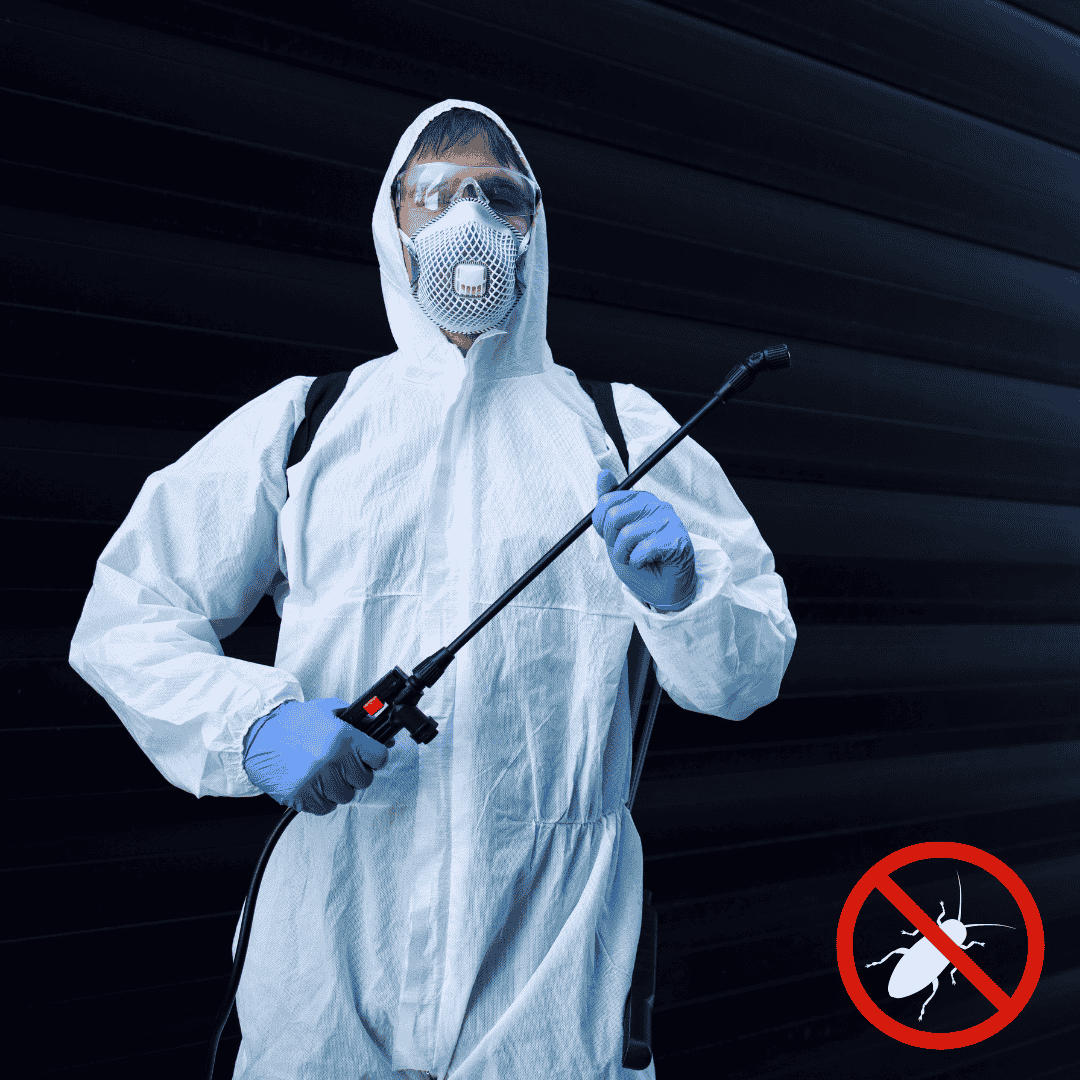

3. Establishing Preventive Controls and Critical Control Points (CCPs)

Preventive control measures are essential for mitigating identified risks. These controls aim to eliminate or reduce hazards to an acceptable level. Critical Control Points (CCPs) are the key locations in the food production process where controls must be applied to prevent or eliminate food safety hazards.

CCPs can include:

a. Temperature Controls

Ensuring food is stored and processed at safe temperatures to prevent microbial growth.

b. Sanitation Protocols

Implementing cleaning procedures to reduce the risk of contamination from surfaces, equipment, and personnel.

c. Ingredient Quality

Verifying that raw materials are sourced from reliable suppliers with safe and traceable practices.

Preventive controls must be tailored to each specific hazard and production process. In addition to CCPs, manufacturers should implement operational procedures to ensure that food safety practices are consistently followed.

4. Monitoring and Verification

Continuous monitoring is crucial to ensure that all preventive controls and CCPs are being implemented effectively. This involves checking critical parameters such as temperature, sanitation levels, and contamination risks at regular intervals.

Verification ensures that the monitoring systems are working as intended. It involves reviewing records, performing tests, and auditing processes to confirm compliance. This may include:

- Routine microbiological testing.

- Physical inspections of equipment and production areas.

- Reviewing cleaning logs and maintenance schedules.

Monitoring and verification help identify deviations from safety standards in real-time, allowing businesses to take corrective actions swiftly.

5. Corrective Actions and Continuous Improvement

When a deviation from safety standards or a hazard is identified, it’s crucial to take immediate corrective action. Corrective actions can include:

- Isolating and removing contaminated products.

- Retraining staff on food safety protocols.

- Adjusting production processes to eliminate hazards.

Once corrective actions are taken, it’s also important to conduct a root cause analysis to understand the underlying issue and prevent recurrence. Continuous improvement should be a key objective, as it ensures that risk management practices evolve over time based on new insights and changing conditions.

6. Documentation and Traceability

Documentation plays a vital role in risk management. Food manufacturers should maintain detailed records of their hazard analysis, risk assessments, monitoring activities, and corrective actions. These records not only demonstrate compliance with regulations but also provide traceability in case of a product recall or investigation.

A robust traceability system enables manufacturers to track every step of the food production process—from raw material sourcing to finished products. This allows businesses to pinpoint the source of contamination and mitigate the impact of any safety issue.

Leveraging Technology for Effective Risk Management

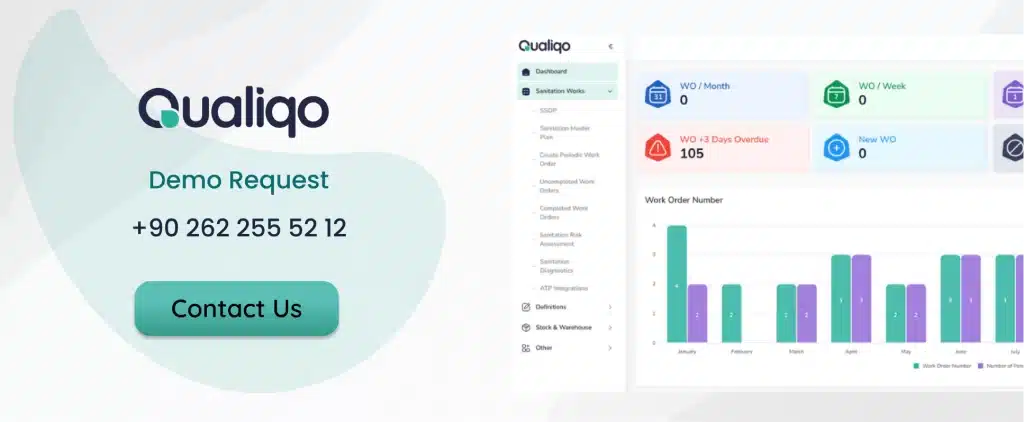

In today’s digital age, food safety management software can significantly enhance your ability to manage risks. Software solutions can automate many aspects of risk management, making it easier to track compliance, monitor processes, and document safety procedures.

Key Features to Look for:

Real-Time Monitoring

Software tools can automatically monitor CCPs and environmental factors such as temperature and humidity, alerting staff to any potential risks.

Inspection and Audit Scheduling

Automated scheduling helps ensure that audits and inspections are conducted regularly and in compliance with safety standards.

Corrective Action Tracking

When issues arise, tracking corrective actions in real-time ensures swift resolution and accountability.

Traceability and Reporting

With automated traceability, manufacturers can track products through every stage of production, enabling quick identification of affected batches in case of a recall.

By integrating these features into your food safety operations, you can streamline processes, improve efficiency, and ensure a proactive approach to risk management.

Next Steps

Did you get enough information about “Risk Management in Food Safety“

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control. We also provide information about the main features and benefits of the software. We help you access the Qualiqo demo and even get a free trial.

Frequently Asked Questions

Risk management in food safety is a systematic process of identifying, assessing, controlling, and monitoring potential hazards that could compromise the safety and quality of food products.

It helps prevent food contamination, ensures compliance with regulations, protects consumer health, minimizes product recalls, and safeguards a company’s reputation.

The three main categories of hazards are:

Biological hazards (bacteria, viruses, parasites)

Chemical hazards (pesticides, allergens, additives)

Physical hazards (metal shards, glass, plastic pieces)