Understanding PRP, OPRP, and CCP in Food Safety and Sanitation Management

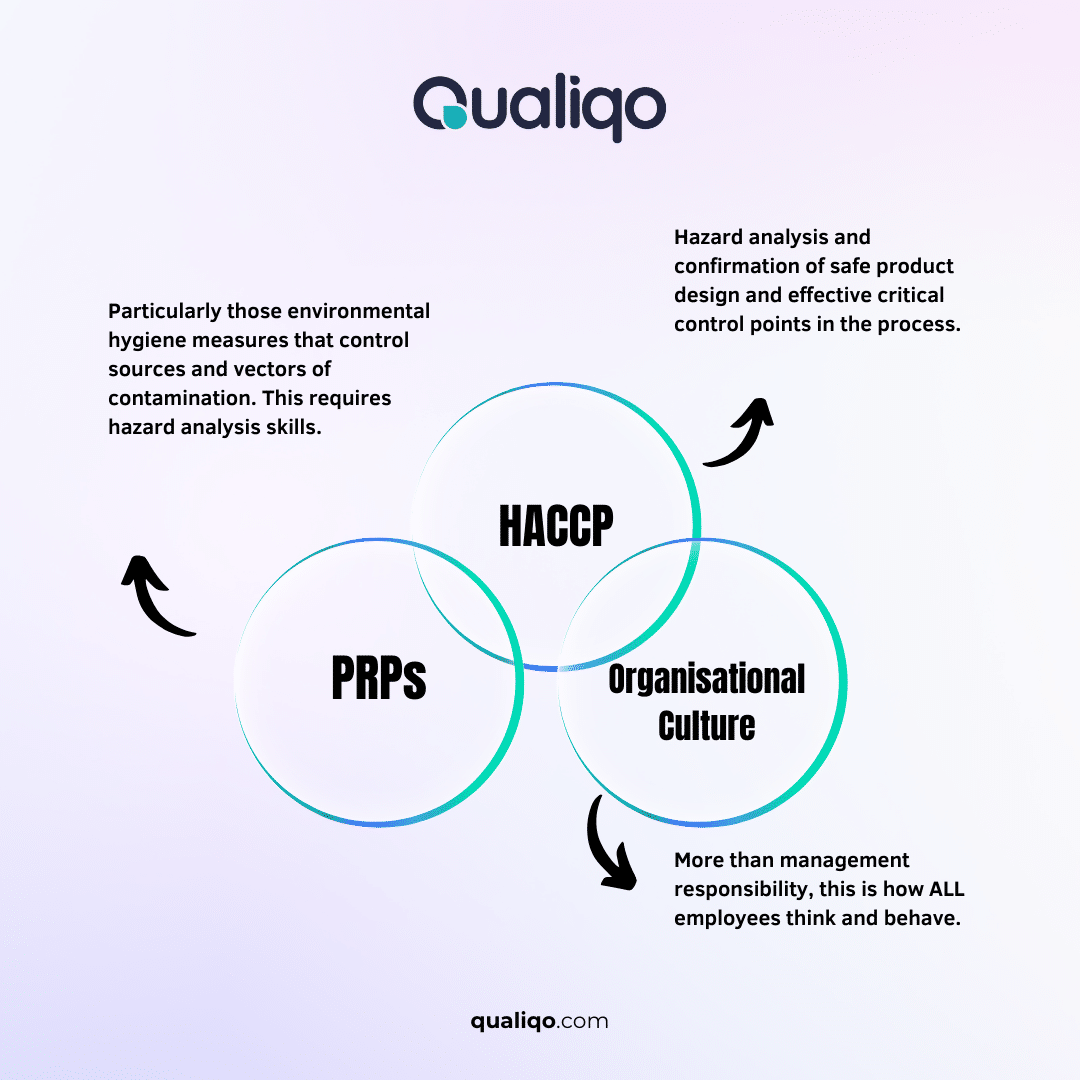

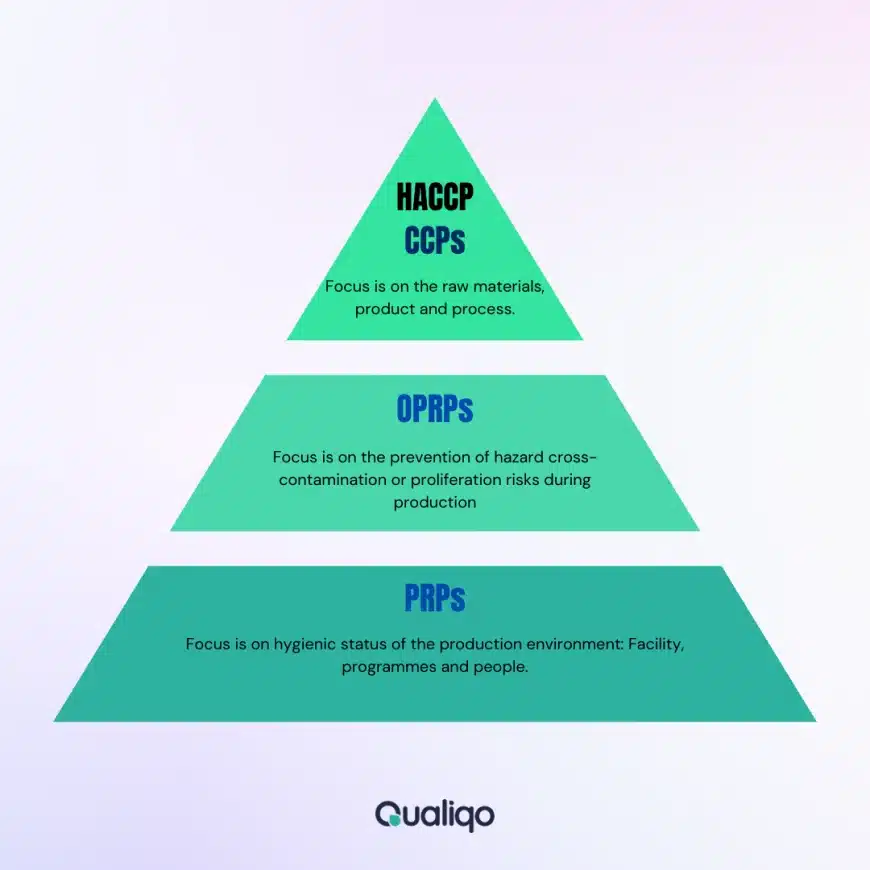

Food safety is a critical concern for any business involved in the production, processing, or handling of food. Implementing a robust food safety management system ensures the health and safety of consumers and compliance with regulatory standards. Three essential components in such a system are PRP (Prerequisite Programs), OPRP (Operational Prerequisite Programs), and CCP (Critical Control Points). Understanding the differences between these elements is key to maintaining an effective food safety strategy.

Prerequisite Programs (PRP)

Prerequisite Programs (PRPs) are the foundational elements of a food safety system. They provide the basic environmental and operational conditions necessary for producing safe food. PRPs address a wide range of issues that can affect food safety, including:

Facility Layout and Design: Ensuring the physical environment supports hygienic practices.

Supplier Control: Managing the quality and safety of raw materials.

Pest Control: Implementing measures to prevent contamination from pests.

Waste Management: Proper disposal of waste to prevent contamination.

Personal Hygiene: Ensuring that staff maintain high standards of personal cleanliness.

Cleaning and Sanitation: Regular cleaning of equipment and facilities to prevent contamination.

PRPs form the first line of defense against potential food safety hazards by creating a safe environment in which food can be produced.

Operational Prerequisite Programs (OPRP)

Operational Prerequisite Programs (OPRPs) are specific actions or measures that control significant hazards in the food production process, which are not managed by PRPs. OPRPs are identified through a hazard analysis and are designed to reduce the likelihood of hazards occurring at critical points in the process. Examples of OPRPs include:

Temperature Control: Ensuring that food is stored and processed at safe temperatures to prevent bacterial growth.

Cross-Contamination Prevention: Implementing procedures to prevent cross-contamination between raw and cooked foods.

Allergen Management: Controlling allergens to prevent cross-contact with allergen-free products.

OPRPs are critical for managing hazards that could directly impact food safety, but they do not require the same level of control and monitoring as CCPs.

Critical Control Points (CCP)

Critical Control Points (CCPs) are steps in the food production process where a control measure is essential to prevent, eliminate, or reduce a food safety hazard to an acceptable level. CCPs are identified through a thorough hazard analysis and are monitored more rigorously than PRPs or OPRPs. Examples of CCPs include:

Cooking: Ensuring that food is cooked to a specific temperature to kill harmful pathogens.

Pasteurization: Applying heat treatment to liquid products to eliminate pathogenic microorganisms.

Metal Detection: Using metal detectors to identify and remove metal contaminants from food products.

Each CCP must have critical limits, monitoring procedures, corrective actions, and verification processes to ensure that the control measures are effective. For example, if a cooking process is a CCP, the critical limit might be a specific internal temperature, and the monitoring procedure could be regular temperature checks with calibrated thermometers.

Integrating PRP, OPRP, and CCP in Your Food Safety Management System

Effective food safety management requires a comprehensive approach that integrates PRPs, OPRPs, and CCPs. Here’s how to ensure your food safety and sanitation management system covers all bases:

1. Establish Strong PRPs: Begin by setting up robust PRPs to create a safe foundation for food production. Regularly review and update these programs to ensure they meet current standards and practices.

2. Conduct a Hazard Analysis: Perform a thorough hazard analysis to identify potential hazards in your food production process. This analysis will help determine which hazards require control through OPRPs or CCPs.

3. Identify and Implement OPRPs: Based on your hazard analysis, implement OPRPs to control significant hazards that PRPs do not address. Ensure that these controls are documented and monitored effectively.

4. Determine and Manage CCPs: Identify CCPs where control measures are critical for food safety. Establish critical limits, monitoring procedures, and corrective actions for each CCP. Regularly verify the effectiveness of these controls.

5. Continuous Improvement: Regularly review and update your food safety management system. Use data from monitoring and verification activities to make informed improvements to your PRPs, OPRPs, and CCPs.

By understanding and implementing PRPs, OPRPs, and CCPs effectively, you can ensure a comprehensive and effective food safety management system that protects consumers and meets regulatory requirements. Your food safety and sanitation management software can help streamline these processes, providing the tools and insights needed to maintain high standards of food safety.

Did you get enough information about “Understanding PRP, OPRP, and CCP”?

Qualiqo is here to help you. It answers your questions about sanitation and hygiene, Lab. & EMP, IPM and Pest Control. We also provide information about the main features and benefits of the software. We help you access the Qualiqo demo and even get a free trial.

Frequently Asked Questions (FAQ)

PRPs are general practices and conditions necessary for maintaining a safe food production environment.

OPRPs are specific actions to control significant hazards not addressed by PRPs.

CCPs are critical points in the production process where control is essential to ensure food safety

OPRPs should be implemented to control significant hazards identified through hazard analysis that PRPs do not manage. These are critical measures that, while not requiring the same level of monitoring as CCPs, are essential for maintaining food safety.

PRPs are the foundational practices and conditions necessary to maintain a hygienic environment suitable for food production. They cover a wide range of basic safety measures such as facility design, supplier control, personal hygiene, cleaning and sanitation, pest control, and waste management.