In this article, we will look for answers to the question What are Food Sanitation and Hygiene Practices? In our previous article, we proceeded on a similar topic and searched for the answer to the question What are the Food Safety System Applications?

What are Food Sanitation and Hygiene Practices?

In the production process of food products, microbial contamination sources that may affect production must be eliminated or minimized in order to obtain a quality, reliable product as a result of the activities.

Food safety must be met in all processes starting from the facility design stage to consumption. It should be audited and monitored with quality management systems and its continuity should be controlled. These practices are building, operation, personnel hygiene rules;

Waste, pest and glass control rules, as well as the rules encouraged by applicable laws and standards related to product processing, storage, distribution and return processes.

Building Hygiene Rules

The hygiene procedure should start from the external environment of the plant and a broad assessment should be made.

Except for offices and some other administrative points, the areas from raw material acceptance to preparation, from preparation to start of production, production areas, storage and shipment areas should be designed and installed to provide appropriate hygienic conditions for food products.

Therefore, starting from the design of the facilities, site selection, interior design, appropriate selection and applications for floors, walls, ceilings, doors and windows, as well as the selection and placement of machinery, tools and equipment to be used, determination and installation of the appropriate electrical installation, lighting and ventilation system for the enterprise are also steps that should be subject to hygiene rules.

Business Hygiene Rules

It mostly covers hygiene practices in the working area. We can explain it with some examples;

Facility cleaning includes hygiene practices in areas such as cleaning and disinfection of the surfaces of the personnel working on the production line, cleaning and disinfection of the surfaces of the tools and equipment to be used in production during the production phase from raw materials to the final product.

Rules in the Production Phase

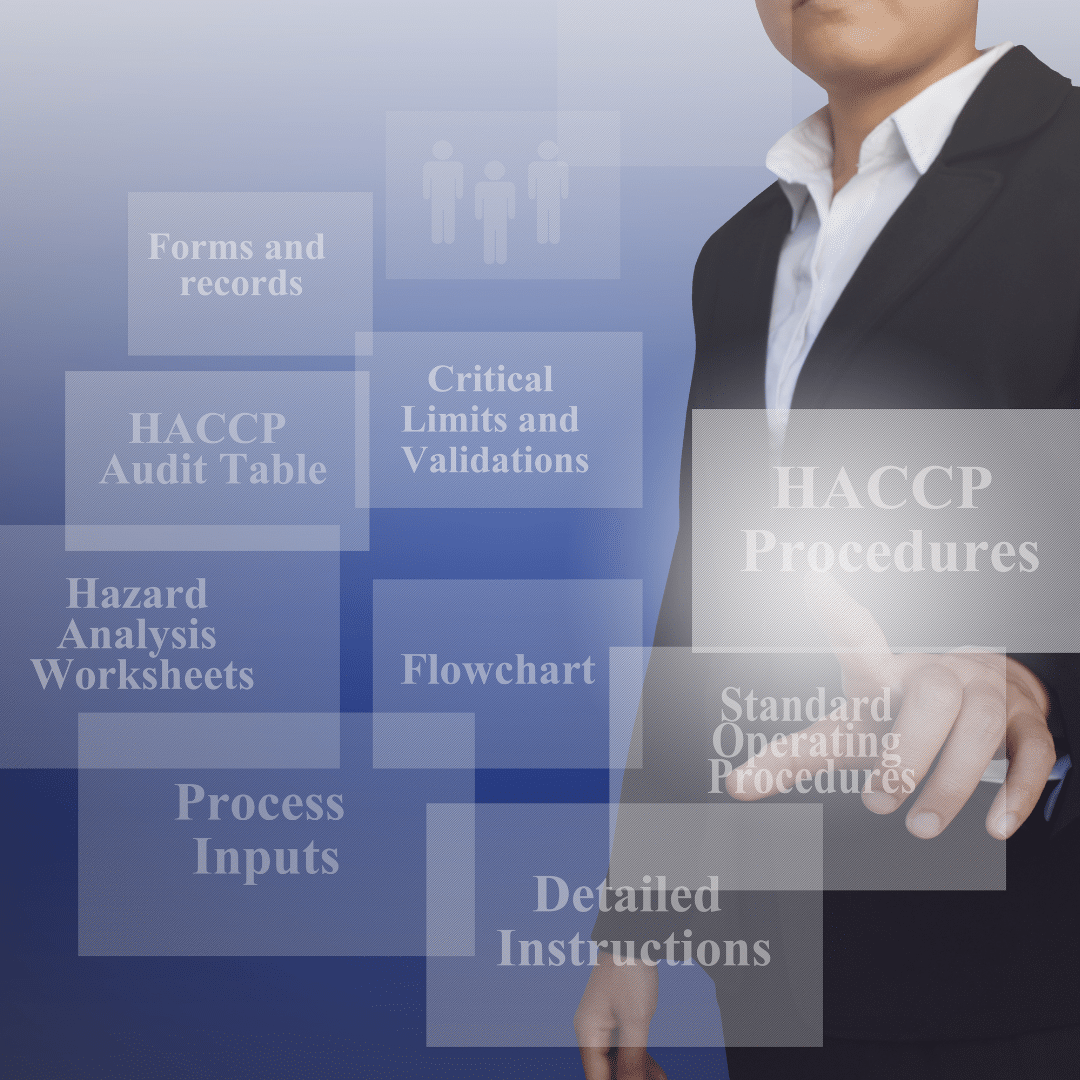

First of all, for the rules that apply at this stage, each enterprise, each facility, must create a clear workflow diagram for each of its products. These diagrams should generally provide information about the production of the product. It is important in this process that the people who examine these diagrams understand that the relationship between the product and the diagram confirms each other.

Starting from the acceptance of raw materials to the relevant areas, certain control follow-up processes should be put in place in all manufacturing processes. From production control to final product controls, from this stage to the end of storage and shipment processes, each stage should be recorded.

Waste and Garbage Control Rules

Changes in environmental laws should be monitored regularly. Plant production plans should be organized to follow these laws. Plant personnel must be informed about the changes and practices.

Other Rules

Procedures should be established for facility entrances and exits and rules should be set for visitors. It is also important to establish control and inspection guidelines for pests, flies, poultry, rodents and other animals in and around the facility.

Planning landscaping around the facility, planning and ensuring inspections and controls for glass products used in the production area, planning and implementing hygiene training for employees who will work on behalf of the company are another important series of rules to be followed.

In this article, we tried to provide you with information about Food Sanitation and Hygiene Practices.